Direct UHT Systems

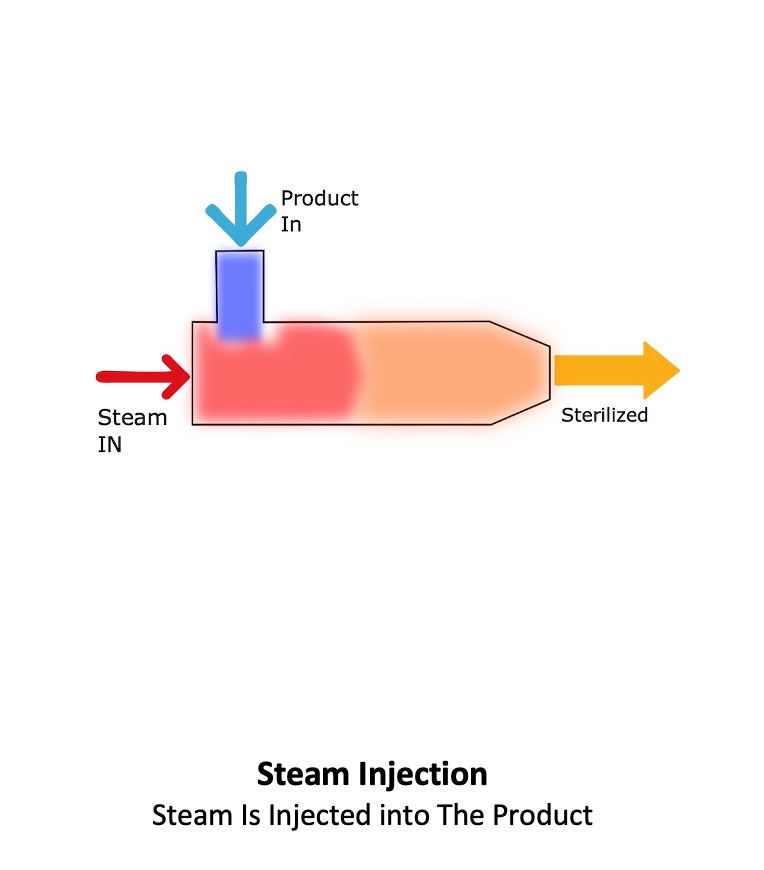

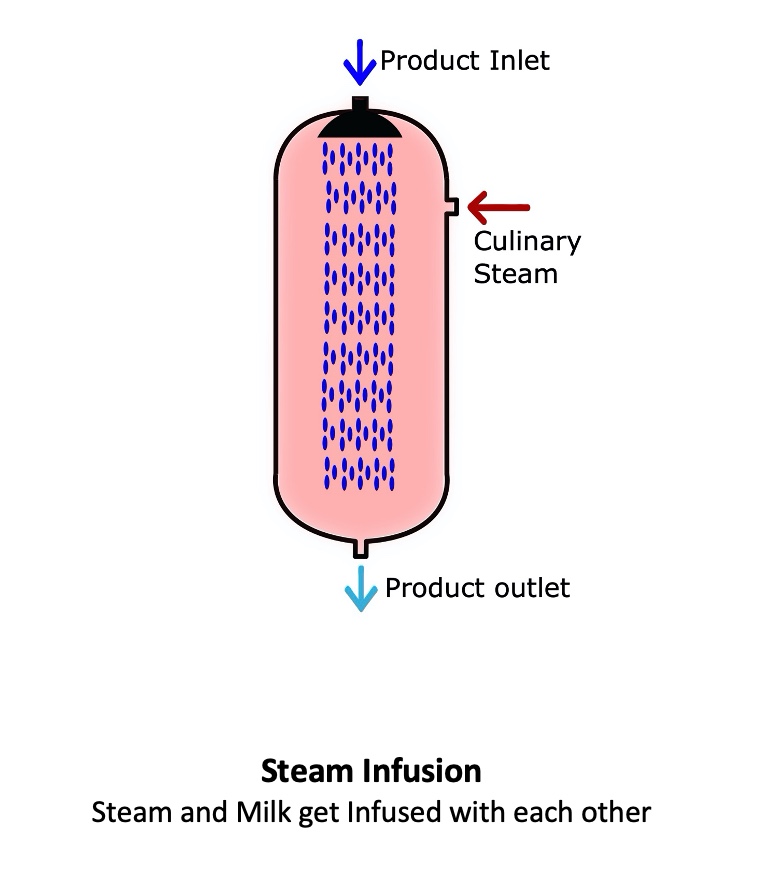

Steam Injection and Steam Infusion Process Description

-

The product is passed through a tubular pre-heater to provide positive flow through the steam-injection or infusion heater. The product is mixed with steam instantaneously in the heater and is ejected or infused into a holding tube of desired length. Example, Skim milk has been heated from 80 degree C to 143 degree C for times ranging few seconds. From the holding tube, the product passes into a vacuum chamber wherein sufficient vacuum is maintained to cool the product to approximately the preheat temperature. The product is removed continuously from the bottom of the vacuum chamber to the aseptic homogenizer and pumped through a tubular cooler to final the temperature.

Advantages of Steam Injection or Infusion

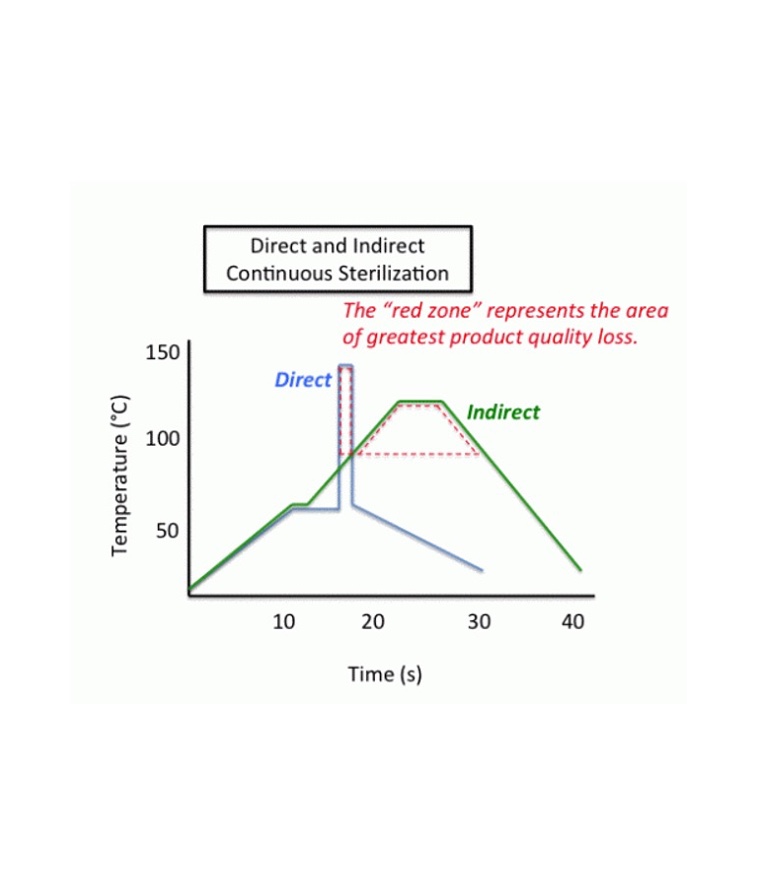

- Fast Heat Up and Cool Down Time Due to Higher Heat Transfer Coefficients Will Not Cause Changes in Flavors, Color and Texture.

- Short Residence Time in High Temperature Final Heaters Will Not Cause Flavor Changes and Color Changes.

- Low deltaT between media and product at Final Heater will not causes burn-on fouling of the heater.

- No Burn-on in Final Heaters Longer Run Times increasing Overall Operational Efficiency.